As an independent project, I decided to design and fabricate my own PC case. The goal of the project was to make a case to my own personal preferences that aren't offered commercially while adhering to the standardized sizes and build quality necessary for it to be usable as a standard computer case. I also wanted to make the case a bit smaller and more compact than most other cases while still having compatibility with full-sized parts.

The majority of the computer case was cut out of 0.04" thick aluminum 6061 sheet metal cut out with a waterjet. While I made the wood paneling on the front out of leftover pallets, I purchased most other hardware and electronic components.

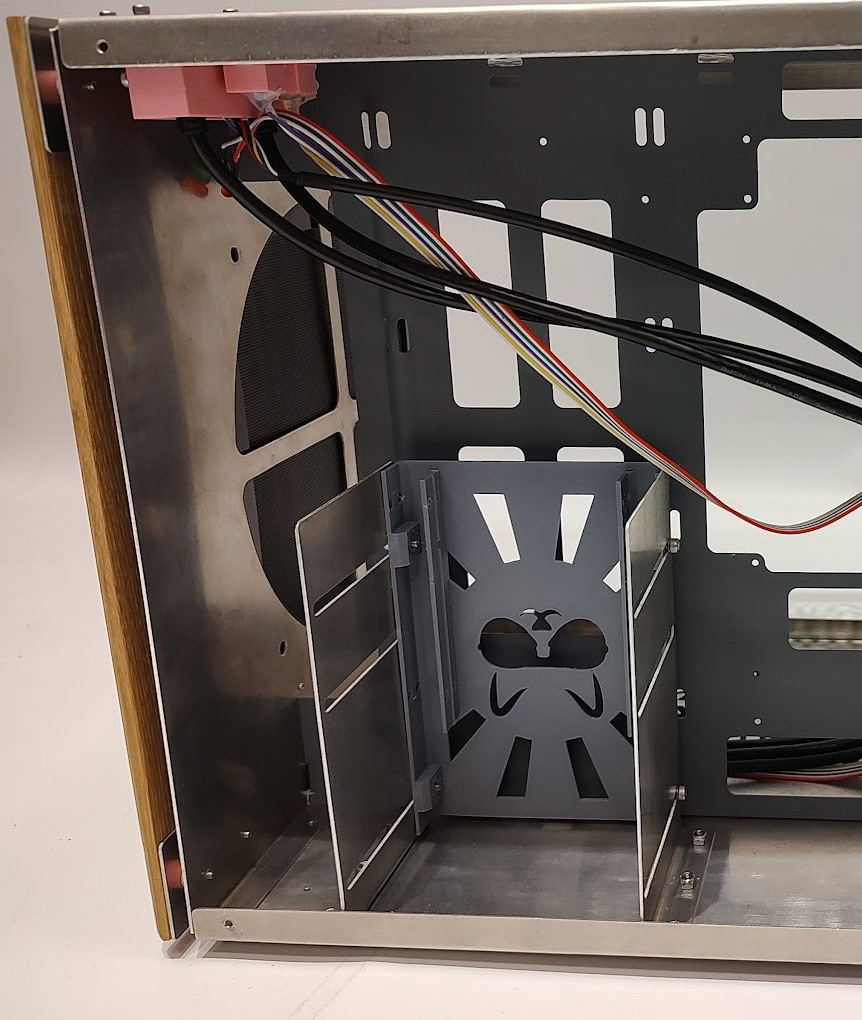

The inside of the case has the cutouts required to fit all of the standard computer part dimensions. For most of them, I referred to ATX standards and attempted to make the case compatible with all various sizes. This involved cutouts for the motherboard, PCI-e slots, fans, and power supply.

One of the key aspects of this case that differs from standard is that the power supply mounts in the rear half of the case. This allows the case to take on a smaller form factor from standard while still being able to use full-sized components. There is also greater flexibility for fan selection, and fabricating the case myself allowed me to incorporate my own aesthetic preferences.

Custom fan grate pattern designed for easy manufacturing on a waterjet

Front IO cutouts with custom wooden buttons

PCI-e cutouts, mounting bracket, and dust covers

Custom HDD and SSD cage

The inner panel of the case is painted to prevent the back of the motherboard shorting

Rear of the Case with rear IO, PCI-e and PSU cutouts

Custom magnetic fan filters for easy removal and cleaning